1-1/2" Silver Wire-O Binding Supplies [2:1 Pitch, 280 Sheet Capacity (approx)] (80/Bx)

Overview

We're overstocked on Wire-O twin loop binding supplies! Check out our variety of clearance wire binding supplies and don't delay; these deals are only available while supplies last.

1.5" silver wire binding spines will bind up to about a 1.25" thick book, which is equal to approximately 280 sheets of standard copy paper. Wire-O® is the most popular binding solution for businesses that need to create professional-quality books. The twin loop spines offer a clean and high-class appeal that is unmatched by any other traditional binding method. Books bound with Wire-O® double-o wires lay flat and the sheets can flip a full 360°. They offer a semi-secure binding method that can only be un-bound if cut off.

Pair these large wire binding spines with you 2:1 pitch Wire-O binding machine for a complete wire binding solution.

Specifications

| Item # | 27112SILVER |

|---|---|

| Manufacturer | James Burn |

| Manufacturer Part Number | WIRECLEARANCE GRP |

| Capacity* | Varies Depending on Size View the Chart in the Product Description for Details |

| Sheet Capacity | Varies Depending on Size View the Chart in the Product Description for Details |

| Binding Style | Wire-O Binding |

| Sheet Size | 8 ½" x 11" [Letter Size] |

| Length | 11" Long |

Description

Clearance Wire-O binding supplies is available in select colors and sizes in either a 3:1 pitch (pronounced "three to one" and with 3 holes per inch) or a 2:1 pitch (pronounced "two to one" and with 2 holes per inch) options. Depending on the capabilities of your wire binding machine, you can choose either pitch or both. Use the wire binding capacity chart below to determine what the best wire binding size for your needs is. And remember, clearance wire bindings are only available while supplies last, so don't delay... buy wire-o twin loop binding supplies online today.

Wire-O Binding Capacity Chart:

How to choose a wire binding size:- Take the entire book being bound and lay it flat on a table, including the covers

- Don't press the stack down, and measure the thickness of the binding edge

- Take the measurement and add 1/8" - that will be the size of the binding spine recommended

| Wire Diameter | Pitch (Holes per Inch)** | Sheet Capacity* | Book Thickness* | Quantity / Box |

|---|---|---|---|---|

| 1/4" | 3:1 or 2:1 | 11-25 Sheets | 1/8" | 100 Wires / Box |

| 5/16" | 3:1 or 2:1 | 26-45 Sheets | 3/16" | 100 Wires / Box |

| 3/8" | 3:1 or 2:1 | 46-65 Sheets | 1/4" | 100 Wires / Box |

| 7/16" | 3:1 or 2:1 | 66-80 Sheets | 5/16" | 100 Wires / Box |

| 1/2" | 3:1 or 2:1 | 81-100 Sheets | 3/8" | 100 Wires / Box |

| 9/16" | 3:1 or 2:1 | 101-120 Sheets | 7/16" | 100 Wires / Box |

| 5/8" | 2:1 | 121-145 Sheets | 1/2" | 100 Wires / Box |

| 3/4" | 2:1 | 146-165 Sheets | 5/8" | 100 Wires / Box |

| 7/8" | 2:1 | 166-185 Sheets | 3/4" | 100 Wires / Box |

| 1" | 2:1 | 186-210 Sheets | 7/8" | 100 Wires / Box |

| 1 ⅛" | 2:1 | 211-235 Sheets | 1" | 100 Wires / Box |

| 1 ¼" | 2:1 | 236-260 Sheets | 1 ⅛" | 100 Wires / Box |

| 1 ½" | 2:1 | 261-280 Sheets | 1 ¼" | 80 Wires / Box |

* Note: Sheet capacities are approximations, determined using standard 20 lb. bond copy paper; the actual sheet capacity will vary depending on the materials being bound.

** Note: The smaller 2:1 pitch wires from 1/4" up to 9/16" are a special-made wire, and are not available in all colors.

Videos

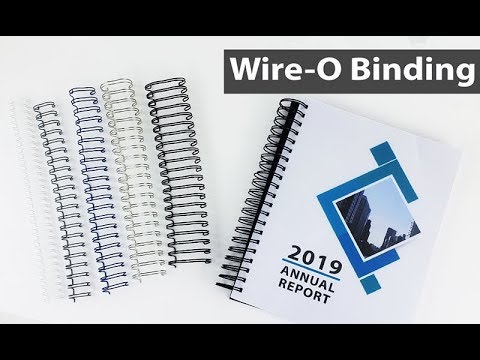

Wire-O Binding Supplies Overview

Wire Binding Machines ► https://www.binding101.com/wire-o-binding-machines

Subscribe ► https://www.youtube.com/c/binding101

Call us ► (866)537-2244

Email us ► info@binding101.com

Learn everything you need to know about twin loop Wire-O binding before you buy in this video. We discuss some of the different options available to you, as well as some of the pros and cons of this professional and simple binding meth... Read More

Wire Binding Machines ► https://www.binding101.com/wire-o-binding-machines

Subscribe ► https://www.youtube.com/c/binding101

Call us ► (866)537-2244

Email us ► info@binding101.com

Learn everything you need to know about twin loop Wire-O binding before you buy in this video. We discuss some of the different options available to you, as well as some of the pros and cons of this professional and simple binding method, so you can make the right choice for your business.

Wire binding is one of the most popular ways to bind client presentations and reports because of the professional finished look. The wires are clean and upscale, and when paired with your custom presentation cover, they make a great impression.

Wire bound books are also very functional. The pages turn a full 360°, they offer perfect registration for a clean look, even with the pages turned, and they will lay flat without needing to crease or hold down the pages.

Wire bound books can also be less than ideal for anyone who may need to handle the wire book for a long period of time, since the wire can bend, and cannot be re-opened to be edited, so if you find a mistake you need to cut the wire and re-bind the pages.

Call (866)537-2244 for bulk pricing or for more information. Or you can buy online at www.binding101.com.

- - -

PACIFIC SUN by Nicolai Heidlas Music https://soundcloud.com/nicolai-heidlas Creative Commons — Attribution 3.0 Unported— CC BY 3.0 http://creativecommons.org/licenses/b... Music promoted by Audio Library https://youtu.be/kbqmEJTr3nU

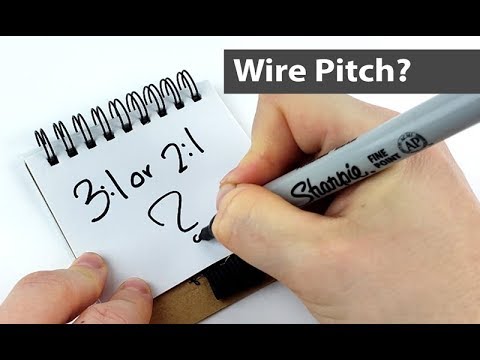

What is a Wire Binding Pitch?

Wire Binding Machines ► https://www.binding101.com/wire-o-binding-machines

Subscribe ► https://www.youtube.com/c/binding101

Call us ► (866)537-2244

Email us ► info@binding101.com

The word “pitch” is used often when it comes to binding documents. It is a term used for every kind of binding that has a punching action/element to it.

In this video, we specifically talk about the term “pitch” as it refer... Read More

Wire Binding Machines ► https://www.binding101.com/wire-o-binding-machines

Subscribe ► https://www.youtube.com/c/binding101

Call us ► (866)537-2244

Email us ► info@binding101.com

The word “pitch” is used often when it comes to binding documents. It is a term used for every kind of binding that has a punching action/element to it.

In this video, we specifically talk about the term “pitch” as it refers to wire binding.

Wire binding, also called twin loop or Wire-O binding, is a popular choice for professionals and businesses for reports, presentations, or anything else that they need to bind together.

Wire binding comes in two standard pitch options, both of which are displayed in a ratio format.

3:1 pitch, pronounced “three to one” and 2:1, pronounced “two to one”. This indicates the number of loops per inch, and correspondingly, the number of holes punched per inch.

Standard letter size 3:1 pitch wire binding spines has 32 loops, while 2:1 wires have 21. The margins on the page are slightly different, which is why you might notice the overall length is slightly different, if you compare them side-by-side.

3:1 pitch wires are made for the thinner documents and books, up to a maximum of about 120 pages, using the wire bind sizes from ¼” up to 9/16”. 2:1 pitch wires are made for the thicker books, up to a maximum of about 260 pages, using the wire diameter sizes from 5/8” to 1-1/4” (1.25”). Binding101 is also excited to offer a special 2:1 pitch wire in the smaller sizes in select colors.

So which binding wire pitch is right for you?

1. Check your machine. If you already have a wire punch and bind machine, then you need to make sure the wire spines you buy are compatible. If your machine punches 3:1, then buy 3:1 wires. Or if it punched 2:1, then buy 2:1 wires. Or if it has both punch patterns built in (often called a “duo punch”) then you can use either, depending on your project.

2. If you don’t have a binding machine yet, then think about the thickness of books that you plan to make. If you truly want the full range of sizes, then 2:1 is your safer bet, since we offer the special smaller 2:1 wires. Most customers who only bind thin books, however, do choose the 3:1 because they like the look of the holes being closer together.

Learn everything you need to know about twin loop Wire-O binding pitches before you buy. In this video we discuss the different options available to you, how to choose a wire pitch, and some things to keep in mind before you buy. With our helpful videos, you can make the right choice for your business.

Call (866)537-2244 for bulk pricing or for more information. Or you can buy online at www.binding101.com.

- - -

PACIFIC SUN by Nicolai Heidlas Music https://soundcloud.com/nicolai-heidlas Creative Commons — Attribution 3.0 Unported— CC BY 3.0 http://creativecommons.org/licenses/b... Music promoted by Audio Library https://youtu.be/kbqmEJTr3nU

Wire Binding Advantages & Disadvantages

Wire Binding Machines ► https://www.binding101.com/wire-o-binding-machines

Subscribe ► https://www.youtube.com/c/binding101

Call us ► (866)537-2244

Email us ► info@binding101.com

It is pretty common knowledge that wire binding is one of the most popular choices! You can find wire bound books anywhere…on journals and notebooks, in schools, in offices for presentations, on art pads, on scratch pads and mini boo... Read More

Wire Binding Machines ► https://www.binding101.com/wire-o-binding-machines

Subscribe ► https://www.youtube.com/c/binding101

Call us ► (866)537-2244

Email us ► info@binding101.com

It is pretty common knowledge that wire binding is one of the most popular choices! You can find wire bound books anywhere…on journals and notebooks, in schools, in offices for presentations, on art pads, on scratch pads and mini books…and the list goes on.

But with that being said, can they really be that perfect?

While wire bindings are a premier way to bind documents, they do have some disadvantages to go along with the advantages. And when you know both, you can easily decide whether wire binding is the best choice for your specific needs.

- - - - - - - - - -

The most obvious benefit of wire binding is the look! They are not only professional, but they are clean and look neat and organized; perfect for the Maria Kondo style household or business. Compared to plastic bindings, these metal wire binding look like a step up.

The twin loop wire style lets you have lay-flat reading (so you don’t have to hold the book open or create a crease in your pages, as you would with a soft cover perfect bound, tape bound, or sometimes thermal bound). The pages also turn the full 360 degrees, which is perfect for space-saving convenience. Once the pages are turned, you will see that they also have perfect registration. That means that the pages remain square with the entire stack, rather than being offset or skewed (as they would be with plastic spiral coil).

We offer only the top-quality wire binding brand: James Burn. Silver wires are a solid wire, while colored wire (including pewter) are created with a special coating that won’t chip of. Other alternative brands typically use a thinner wire, and we have heard complaints of customers switching over to us saying that the colors chipped quickly.

One thing to keep in mind is that, because they are made of a metal, they can be bend. This makes them able to close, but this also means that they can get bent if handled roughly. That is why wire binding is typically best used for books used by adults, and that might not be handled daily, or passed from person to person. As our binding wires get larger, they also get a bit thicker, making them more durable and resistant to bending, as well as stronger to handle the heavier page books.

Sometimes closing a perfect circle is a bit difficult. Depending on your wire closing machine, this may or may not be an issue for you. To get the best and most perfect close, you will want a closer that has a gliding adjustment (so you can fine tune the placement) rather than just a “click, click” from size to size setting (does that make sense?).

Wire binding is secure because the wire cannot be edited once bound. That means that on order to change out a page or fix a typo, you have to actually cut the wire off (you can use wire cutters) and re-bind them with a new wire spine. This could also be considered a disadvantage, depending on your opinion and application.

One important thing to understand if you’re new to wire binding is that it requires two different punching patterns in order to bind the full range of wire sizes. Called 3:1 and 2:1 pitch (pronounced “three to one” and “two to one”), the hole pattern (and corresponding loop pattern of the wire) will have either 3 holes per inch (32 holes on an 11” edge) or 2 holes per inch (21 holes along an 11” edge). Because these are these two patterns, you will need either two machines, a duo punch, or a disengageable die punch to be able to bind with every wire size there is. 3:1 pitch wires are made for the thinner documents and books, up to a maximum of about 120 pages, using the wire bind sizes from ¼” up to 9/16”. 2:1 pitch wires are made for the thicker books, up to a maximum of about 260 pages, using the wire diameter sizes from 5/8” to 1-1/4” (1.25”).

EXCITING NEWS: We now offer specially-made smaller wires in the 2:1 pitch for select colors! Keep in mind that the large majority of customers have a strong preference of the more tightly spaced 3:1 hole pattern when binding their thinner books.

And lastly, in a spine-by-spine comparison, wire binding is more expensive than the plastic binding alternatives.

- - - - - - - - - -

Now that you know the wire bind advantages and wire bind disadvantages, what are your thoughts? Is twin loop metal wire binding the best way to bind?

If you need more information, click the links above or call our experts at (866)537-2244. Or you can buy online at www.binding101.com.

- - - - - - - - - -

PACIFIC SUN by Nicolai Heidlas Music https://soundcloud.com/nicolai-heidlas Creative Commons — Attribution 3.0 Unported— CC BY 3.0 http://creativecommons.org/licenses/b... Music promoted by Audio Library https://youtu.be/kbqmEJTr3nU

![Close-up of large, shiny metal loops arranged in a 2:1 pitch configuration, showcasing the sturdy and professional design of 1-1/2" Silver Wire-O Binding Supplies [2:1 Pitch] for thick document binding.](https://www.binding101.com/media/catalog/product/cache/4806281b0b4d25b598359cb75ace4a3c/s/i/silver_1024x1024_2.jpg)